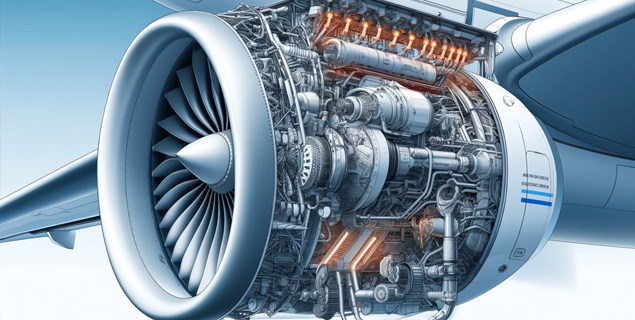

DE ICE Air Intake System is used for air intake into jet engines and propellers to eliminate the ice from their way in aviation. Systems that could do this would include electric heating elements, air-bled from the engines themselves, or chemical deicers that would either melt the ice or prevent its formation.

what does de ice air intake system mean

The purpose is to keep the ideal airflow and not allow any ice into the engine, which damages or reduces performance.

In other words, the principles are similar for ground-mounted engines or those applied in industries. de-ice air intake system it is critical that the air intake paths do not have entrained ice or ice collected over them, lest performance, mechanical integrity, and operational safety be impaired.

The technologies and strategies used must vary greatly depending on the application, engine type, environmental conditions, etc. The sensors in modern systems usually automate this to detect ice formation, thus triggering the DE ICE Air Intake System where necessary but ensuring that activity goes on without interruption by man.

how to de ice air intake system: 5 Ways

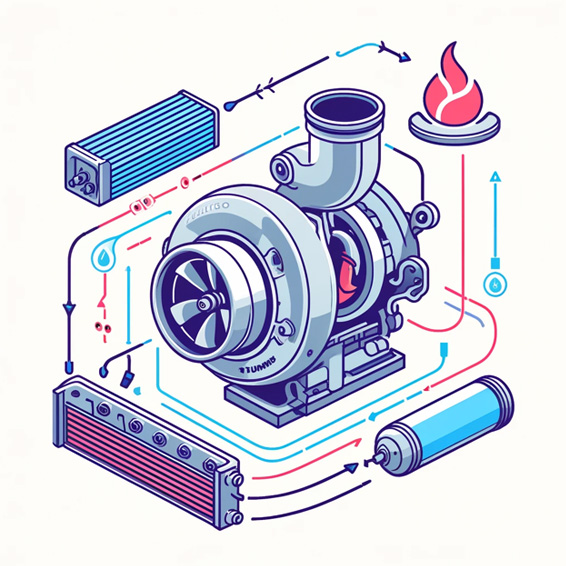

De ice air intake system, especially in aviation or automotive, is getting rid of or preventing the development of ice that would tend to hinder a complete airflow system. All these could have severe implications for the engine performance and, in so doing, safe operation. The applied methods could be adaptable to the case in point (such as a plane, a vehicle, or industrial machinery); in general, these include:

Electrical Heating

Description:

Electric heating elements installed in or near the de ice air intake system area. The sensors act upon determining cold conditions that should signal ice, firing the heater to warm the air or surface as soon as possible so that ice formation will not push through.

Applications:

Automotive has almost the same commonality with the aircraft. For instance, in cars, some car air intake systems will have electrical de-icers or heaters in the intake manifold.

Bleed Air

Description:

Air bled from the engine’s compressor stage has entered critical areas, like the air intake, for ice protection. The temperature within these areas is kept too high for ice formation, and hot air is used to prevent formation because it will be above the freezing point.

Applications:

This method is primarily used in aviation, especially jet engines.

Chemical De-icers

However, it is possible to use these chemical agents, applied in the air intake area, to lower the water’s freezing point. These chemicals can also inhibit ice formation, and this will happen even at temperatures much below the freezing point.

Less common in air intakes, the direct application is used in related areas such as fuel lines or external surfaces.

Mechanical Devices

Systems could include devices like pneumatic wing de-ice boots would physically break the ice by using bleed air or vacuum pumps to dislodge ice during both inflation and deflation cycle. Ice protection boots are more frequently used on the leading edges of wings and propellers but can be applied to air intakes using similar principles.

Applications:

It is mainly used on aircraft surfaces but illustrates a mechanical approach to de-icing.

Manual Removal

Description:

Ice may also need manual removal, either by lifting it physically or, in some cases, even using portable heaters to melt the ice in and around the air intake.

Application:

Most common in ground-based vehicles and small aircraft, it is generally used to cross-check for safety before starting the engine.

Implementation Considerations:

Safety:

It should be ensured that the de-icing method being applied does not trigger other safety implications, like overheating or chemical contamination.

Efficiency:

The de-icing method should not significantly impact the engine’s performance or fuel efficiency.

Environmental Conditions:

Choose the deicing method for the environmental conditions and expected severity of ice formation.

de ice air intake system cost: explore

The cost of the de-icing air intake system may vary greatly according to the type of system, aircraft, automotive, industrial machinery, and the particular de-icing technology used, or how complex the installation is made. Here is a very rough breakdown by application.

Automotive De-icing Systems

While there is generally no such thing as a dedicated system to de-ice air intake that comes standard in cars or trucks, electrically heated air intake parts may be available or be sold as a $50 to $500 aftermarket solution for parts alone, not including installation.

Most other commercial vehicles running in such severe conditions would use more specialized solutions, some running into several thousand dollars if you contemplate advanced heating solutions or any type of custom installations.

Industrial and Other Applications

Industrial machinery such as generators or compressors, when in operation in cold climate zones, may require solutions for de-icing, just like those applied in aviation or automotive applications.

Estimates for costs can vary substantially—from the hundreds to several thousands of dollars—for custom or largescale systems, depending on the intake size, environmental conditions, and machinery used.

Aircraft De-icing Systems

Retrofitting a basic pneumatic de-ice system with electrically heated elements for small aircraft may range from the low thousands to the high tens of thousands, depending on aircraft size and system complexity.

On the contrary, complex, expensive de-icing systems most frequently have a basis from bleed air or complicated electrical systems. The installation cost is calculated in the total cost of an airplane, while the cost of exchange or upgrading runs up to hundreds of thousands of dollars due to complexity and certification.

General Considerations

Professional installation:

There would be an extra cost incurred for professional installation. For systems relatively complicated and requiring special knowledge for their safe and effective handling, the cost of professional installation can be quite high.

Operation and Maintenance:

Some of the de-icing systems have high power consumption-related operation costs, such as electrical heaters or bleed air systems. Even the maintenance costs vary in relation to the complexity of the systems and accessibility.

de ice air intake system repair cost

The cost to repair a de-ice air intake system varies widely, depending on its design, the amount of damage done, or the fault of the air intake system. Lastly, its specific application is whether used for aircraft, automotive, or industrial machinery. However, some general guidelines and factors will affect the repair costs.

Automotive De-icing Systems

Passenger Vehicles:

Although not in as many words and probably not having an air intake de-ice system, related in principle, modern passenger vehicles may still have associated components in the form of heated intake manifolds. They will also tend to be much cheaper to repair than aircraft, with systems generally ranging from $100 well into the thousands, depending on the make and model of a vehicle and the type of repair it requires.

Commercial Vehicles:

These are generally bigger-sized vehicles with better de-icing systems for rougher conditions. The repair may cost a lot, but generally, it is just a small fraction of what you may pay for an aircraft, depending on how elaborate the system is.

Industrial Machinery

Industrial Use:

The cost to repair an industrial machine de-icing system is comparable to that of general aviation or commercial vehicles’ de-icing systems, as long as it is less complicated. Simple changes to the heater element could run a few hundred dollars, while more complicated repairs—especially for large or specialized equipment—can reach thousands.

Aircraft De-icing Systems

General aviation aircraft:

The cost of repairing or replacing a component of a deicing system on general aviation aircraft, which are small or medium in size, will run from as little as a few hundred dollars to several thousand, depending on the nature of the repair and whether it involves electrical heating elements, pneumatic boots, or other system components.

Commercial Aircraft:

Repairing commercial aircraft can cost tens of thousands of dollars, especially when it involves critical safety requirements and complex systems, such as replacing many parts or recalibrating sensors and control systems.

Factors Affecting Repair Costs

Parts:

Replacement parts range from relatively cheap sensors or heating elements to more expensive and complex components, such as pneumatic de-icing boots and electronic control units.

Labor:

The actual price for repair labour varies depending on the system’s accessibility, the expertise required for diagnosis and repair, and regional labor rates.

Downtime:

Downtime for necessary repairs was of major interest in business operations, as it could add to the overall cost, mostly in terms of operational productivity or revenue loss.

Considerations

Preventive Maintenance:

This involves regular and continual checkups, so problems are determined in due time before they require more expensive repairs. In other words, they are the potential preventive dollar savers over the long haul.

Warranty/Support:

Check if the existing warranties or support contracts cover the repair; they may greatly minimize out-of-pocket expenses.

Professional Assessment:

Due to the differences in systems and potential safety implications, especially in aircraft and industrial applications, professional assessment becomes necessary to obtain a correct estimate of repair costs.

The actual cost to repair a de ice air intake system is best gauged by seeking the advice of a certified professional or a service provider who would assess the system and its condition.

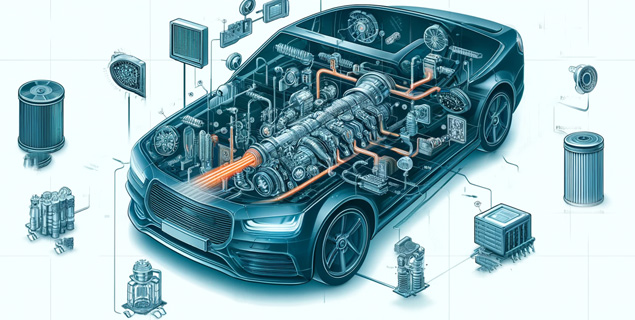

de ice air intake system chevy

In fact, not likely even to feature in the same de ice air intake systems that aircraft or industrial machinery might use is the de ice air intake system of a Chevy Cruze, malibu, camaro—or any modern car with similar configurations. However, temperatures ranging from -40°C to 5°C do not guarantee an ice-free vehicle since separate parts within the car will still lead to ice formation and consequently influence performance. While the Chevy Cruze—like most modern cars—is engineered with systems that should perform well under even the most greatly varying temperatures and conditions, there are instances where ice can be a real problem, such as throttle body ice or, for that matter, mass airflow (MAF) sensor icing.

Here’s how you might address ice-related issues in the air intake system of a Chevy Cruze, Chevy Malibu, Chevy Camaro:

Preventive Measures

Engine Coolant:

Ensure that the level and concentration of your engine coolant are adequate. Some vehicles will use coolant lines, which run to the throttle body to aid in regulating temperatures and icing conditions in cold weather.

Regular Maintenance:

Keeping the air filter clean and replacing it from time to time helps keep the cooling airflow to a minimum, thereby reducing the chances of moisture collection and freezing.

Identifying Issues

Check Engine Light:

Under these conditions, particular ices and some of their components, such as the MAF sensor, may be affected, and the check engine light can illuminate these. The diagnostic scan tool can be used to determine whether there is an error code concerning the intake of air.

Symptoms of performance:

Rough idling, stalling, or difficulty starting in cold weather, all of which may indicate ice formation in the air intake system.

Dealing with Ice Formation

Throttle Body:

Ice can accumulate around the throttle body. The throttle body should be removed and cleaned if throttling of ice is suspected. In some cases, gentle heating with a hairdryer could help melt the ice; attention should be paid not to overheat any part.

MAF Sensor—Ice or Condensation on the Sensor—The MAF sensor could have ice or condensation on it; if it does, incorrect mixtures of air/fuel could be caused. On suspicion of icing the MAF sensor, carefully remove it and clean it with a cleaner specifically made for MAF sensors.

Professional Assistance

However, if you are experiencing persistent problems—those you believe might be related to ice buildup in the air intake system—or maybe that’s just not how you roll, you should see a professional. A qualified mechanic will be able to diagnose and correct problems more accurately.

Aftermarket Solutions

Cold air intake systems designed for cold weather, or aftermarket products and solutions, may be available for vehicles often operated in a frigid environment. In the latter case, these systems are engineered to minimize moisture entry and subsequent freezing. While the Chevy Cruze and other similar vehicles can indeed perform well across a lot of environmental conditions, it is to be particularly noted that doing the right kind of maintenance is essential to know how such extreme coldness can affect your vehicle and, in turn, will be the prime thing to avoid such issues related to ice.

Conclusion

De ice air intake system strategy compromises between the proactive (anti-ice) and reactive (de-ice after the ice has built up) approaches, which are particularly adapted to the needs stemming from the engine and operation

DIY solutions may present themselves, for instance, in the automotive and some light industrial cases, as viable alternatives offering reduction in the costs incurred. Nonetheless, such solutions come with the effectiveness that can only be limited and the possibility to be a subject to damage in cases when they are not properly executed. With so many varied applications and systems, to determine which is best suited for your particular need would be best evaluated by professionals, or by the manufacturers of said applications and systems.